Introduction

In advanced manufacturing industries, especially automotive and metal part production, edge quality and the way components are joined are of great importance. One common method to reinforce edges and create mechanical connections is the hemming process—a technique that not only enhances strength but also provides a uniform and professional appearance to the final product.

With technological advances, traditional hemming methods relying on dies and presses have been replaced by flexible robotic systems. In this article, we will cover the principles of hemming, its basic equipment, and the advantages and applications of robotic hemming—a method increasingly adopted in modern production lines.

Hemming and Forming with Rollers: Introduction to Tools and Basic Equipment

The hemming process is a key step in shaping the edges of metal sheets, commonly used in automotive, home appliance, and fine metal part manufacturing. In this method, the edge of the sheet is folded onto itself, improving both appearance and edge strength. This process is often used to mechanically join two sheets without welding, riveting, or adhesives.

Among various hemming techniques, Roller Hemming is recognized as a precise, safe, and gradual forming method. Unlike impact or press hemming, where the bend is completed in a single step, roller hemming gradually bends the edge over several passes. This method is especially suitable for parts with curved or complex shapes.

Main Hemming Equipment

Roller Hemming Tool

At the heart of this process is the roller hemming tool, which consists of a precisely engineered metal roller. This tool moves along the edge of the sheet, gradually bending it. The roller surface must be perfectly smooth, wear-resistant, and have a specified radius to prevent damage to the sheet. The movement is usually carried out in controlled phases, bending the edge initially and fully flattening it in subsequent passes.

Roller Hemming Bed

The hemming bed or base provides a sturdy and precise surface for the workpiece. It may include fixtures or clamps to secure the part during roller movement. The design of the bed plays a critical role in the final quality of hemming, particularly for parts with curved or multi-surface edges.

Robotic Hemming: Intelligent Flexibility in Modern Production

Traditionally, hemming—especially in the automotive industry—was performed using heavy presses and custom dies. While accurate, these methods required significant investment, large space, and long lead times for die design and fabrication. With the advent of robotic forming technology, Robotic Roller Hemming systems have emerged as an economical, precise, and flexible alternative.

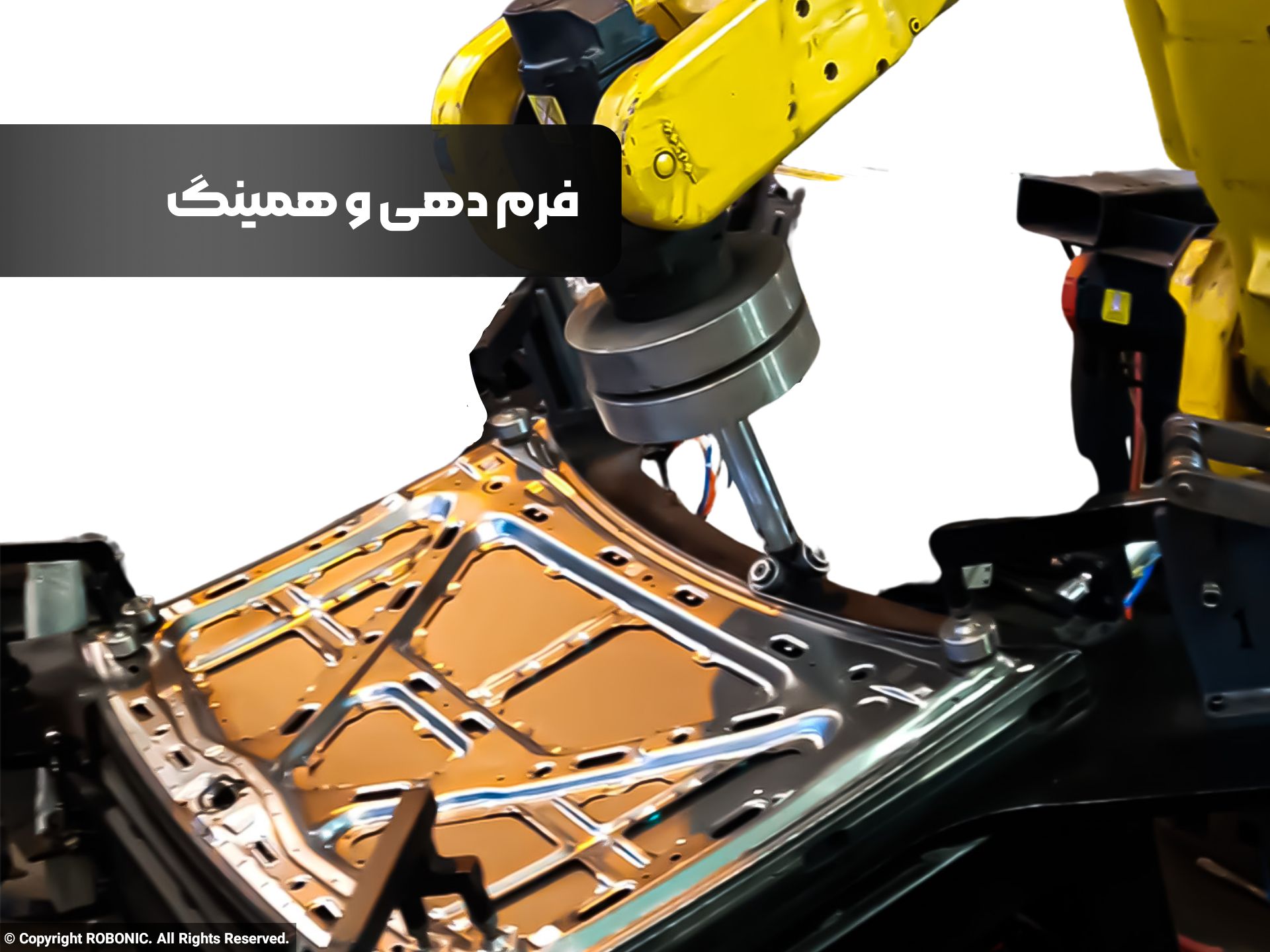

In robotic hemming, a multi-axis robotic arm is equipped with the roller hemming tool and moves along the edge of the part according to a programmed path. By controlling speed, pressure, and movement angle, the robot performs gradual, precise, and uniform bending. This method is particularly effective for parts with curved or angled geometries.

Key Advantages of Robotic Hemming

- Significant cost reduction for low to medium production volumesIn traditional methods, custom dies had to be designed and manufactured for each part, which was not economical for low-volume production. In contrast, robotic hemming eliminates the need for physical dies, greatly reducing setup costs.

- Capability to use a single system for multiple productsA robotic arm equipped with a hemming tool can work on various parts with different shapes by quickly changing the program. This feature is especially valuable in production lines handling multiple diverse products.

- Exceptional flexibility for modifications and adjustmentsIn robotic hemming, desired changes can be easily implemented simply by modifying the robot’s motion program. This minimizes the time required for reverse engineering, testing, and adjustments.

- Elimination of limitations for complex shapesA multi-degree-of-freedom robotic arm can perform hemming on three-dimensional, curved, angled, and other complex parts without compromising quality—something that was very difficult or even impossible with press or die methods.

- Faster setup and changeover compared to traditional methodsWhile designing and manufacturing traditional dies can take weeks or months, robotic systems can be set up within hours or days by simply configuring the tool path in software and integrating it with the hemming bed.

A Selection of Projects Completed by Robonic

Conclusion

Robotic hemming represents a significant step toward smarter and more optimized metal production. By utilizing robotic arms equipped with roller tools, edge forming can be carried out with high precision, exceptional flexibility, and in a short amount of time. Unlike traditional methods dependent on expensive dies and heavy presses, robotic hemming requires lower startup costs, supports multiple products, and allows rapid design adjustments, meeting the dynamic demands of modern industries.

In a world where competition increasingly revolves around reducing production time and improving quality, adopting solutions like robotic hemming is a smart investment for a more agile and precise future.