Project Information

- Client: Beverage Manufacturing Company in Tehran

- Industry: Food & Beverage

- Robotic Solution: Palletizing

Technical Specifications

- Concept Design and Overall Line Layout

- Supply and Commissioning of a KUKA Robot Model KR210/L180 with KRC2 Controller

- Line Control and Coordination PLC: Siemens S7-1200

- Industrial Network: PROFINET

- Custom Gripper Fabrication for the Robot to Lift Multiple Bottles Simultaneously

- Design and Manufacturing of Infeed Servo Conveyors, Traffic Control System, and Grouping System

- Design and Manufacturing of Output Pallet Roller Conveyors

- Manufacturing of the Pallet Magazine (Pallet De-Stacker) Machine

Project Stages

Layout Design of the Line

At this stage, the concept and overall layout of the line were designed based on the information provided by the client. There were several constraints regarding the installation of the conveyors, including space and dimensional limitations. Using precise design and simulations, the initial concept—which included the infeed servo conveyors, traffic control system, and grouping unit—was developed.

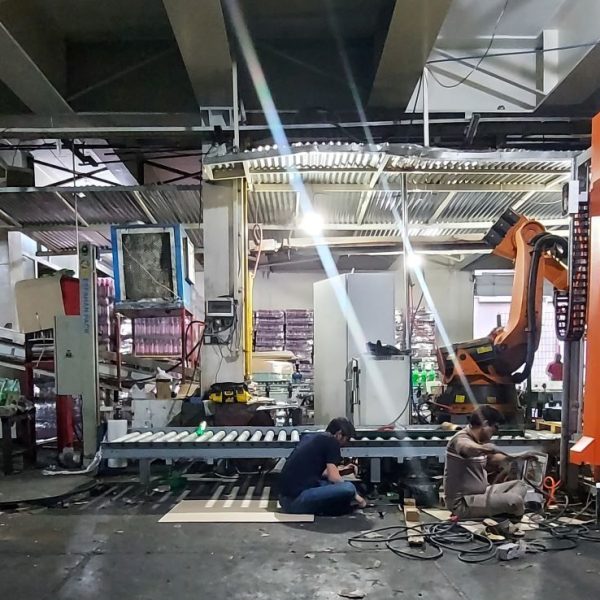

Equipment Procurement and Initial Demo Setup

The minimum required equipment, including the gripper and the pallet conveyor rollers at the output, were supplied and initially set up as a demo outside the main production area.

Moving the Equipment Inside and Initial Setup

After initial testing, the equipment was transferred inside the facility, and the preliminary setup was completed at the final installation location. During the final commissioning, additional equipment—including the automatic pallet magazine (pallet de-stacker) and the layer placer (all manufactured by Rebonik)—were installed and integrated with the main production line.

Completion of the Line and Final Commissioning

Once all components were installed and the final adjustments were made, the palletizing line became fully operational. The system is capable of palletizing up to 14,000 bottles per hour.

Before installing this robotic cell, six workers per shift were required for manual palletizing, who faced significant ergonomic issues and injuries due to poor working conditions. Additionally, the output capacity of the line was limited by the manual labor rate.